Incorrect install or time for a tune?....

#16

#17

It looks like you didn't replace the two guide pins on each side of the plenum. Might want to take those out (I think you can use 4mm socket) and replace with some m6 bolts. Check the lines for cracks as well. I had to replace one of mine not to long ago due to it cracking.

I'm off work tomorrow Jeff and can take a look in the morning or if you want to swing by tonight too.

I'm off work tomorrow Jeff and can take a look in the morning or if you want to swing by tonight too.

I'm referring to the small gold nuts sticking out (1 near the oil filler cap and the other on the left side near a vacuum hose)

#21

Thanks for the imput guys.

I just got back from Home Depot and they dont have any M6 nuts / bolts (go figure)

But I found out that I can remove them with a standard 4mm socket (thanks pappa). Can I just remove the gold guid pins and replace with regular hex bolts? or is that not an option?

I just got back from Home Depot and they dont have any M6 nuts / bolts (go figure)

But I found out that I can remove them with a standard 4mm socket (thanks pappa). Can I just remove the gold guid pins and replace with regular hex bolts? or is that not an option?

#22

I'm pretty sure I have a bunch of those bolts lying around Jeff. Yes, you can replace them with m6 x 1.00 bolts. Without a spacer, I think they need to be 35mm long? I'll have to check that when I get home but I think bigc knows off the top of his head

Last edited by G35Papa; 05-13-2010 at 05:10 PM.

#27

Thanks Chris (G35Papa) for helping me diagnose the source of my leak this morning!!!! Couldn't have done it without you man. Thanks!

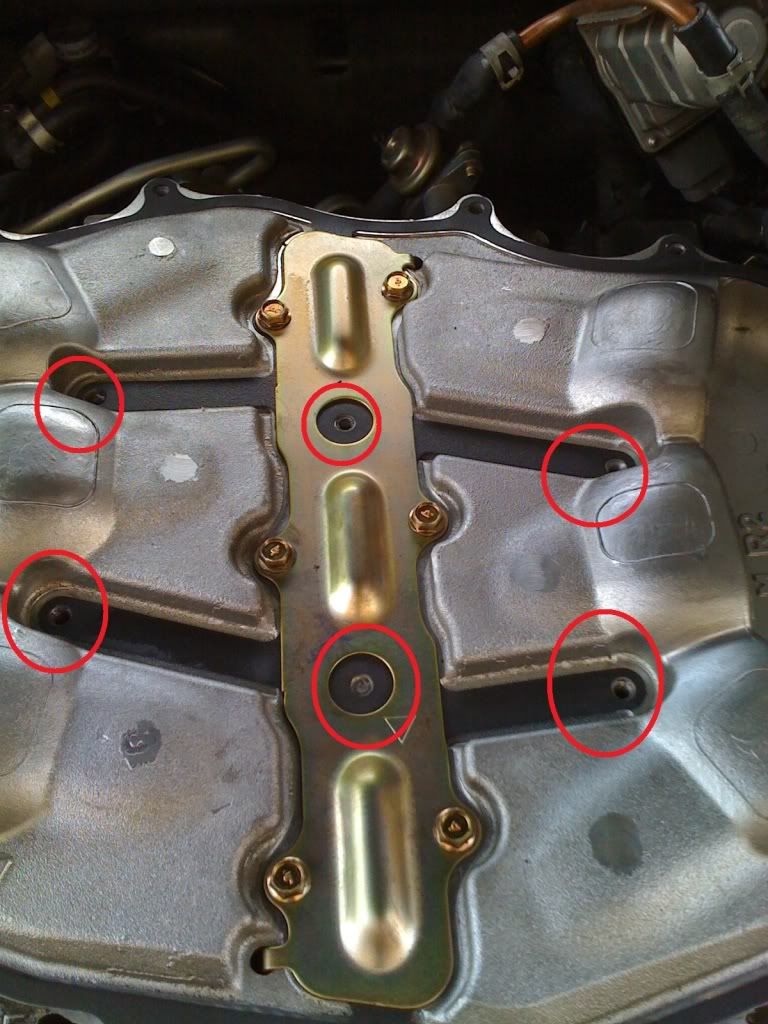

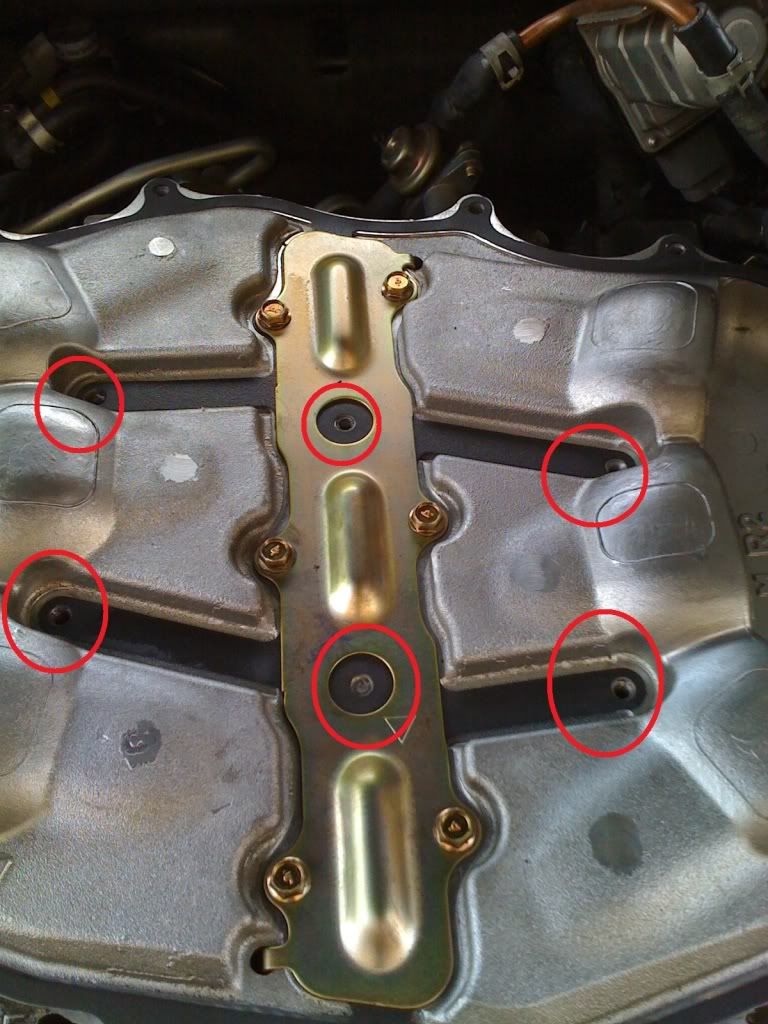

For those of you interrested, the problem was inside the mrev2. the stock plenum has 6 screws that bolt down into the lower plenum, where the crawford only has 2. I didnt know the holes actually go all the way through the Mrev2 therefore causing 4 of the holes to allow open air to seap in. we plugged them up with bolts and now it works perfectly. see pics

as you can see, the outer 4 holes on the lower plenum dont get used by the crawford. my own ignorance for not reading the instructions and thinking it was something much more complicated. just plugged up the holes and bolted it down.

and thinking it was something much more complicated. just plugged up the holes and bolted it down.

also found that the reason for the missing bolt not goin into the crawford was due to the thread stripping inside the lower middle Mrev hole . but it is still airtight and runs fine.

. but it is still airtight and runs fine.

Thanks again Pappa for taking time out of your morning to help me!!!!

she runs smooth now and sounds great at WOT!!!

For those of you interrested, the problem was inside the mrev2. the stock plenum has 6 screws that bolt down into the lower plenum, where the crawford only has 2. I didnt know the holes actually go all the way through the Mrev2 therefore causing 4 of the holes to allow open air to seap in. we plugged them up with bolts and now it works perfectly. see pics

as you can see, the outer 4 holes on the lower plenum dont get used by the crawford. my own ignorance for not reading the instructions

and thinking it was something much more complicated. just plugged up the holes and bolted it down.

and thinking it was something much more complicated. just plugged up the holes and bolted it down. also found that the reason for the missing bolt not goin into the crawford was due to the thread stripping inside the lower middle Mrev hole

. but it is still airtight and runs fine.

. but it is still airtight and runs fine. Thanks again Pappa for taking time out of your morning to help me!!!!

she runs smooth now and sounds great at WOT!!!

#30

Now all I gotta do is Dyno Tune it and put all those respritory mods to their full potential.

Thread

Thread Starter

Forum

Replies

Last Post

papa's garage makes everything better

papa's garage makes everything better