E85 DIY Walbro 485 with E-Flex, Haltech

#1

E85 DIY Walbro 485 with E-Flex, Haltech

I am Upgrading to E85, I have a Haltech Plug and Play and E-Flex sensor on order.

Once I get the E-Flex sensor I will add that the guide !

If you didnít have a RFS already you would need rails and the lines for the rails plus the fuel basket fuel regulator replacement part from CJM.

Here is what the AAM stage 1 RFS Fuel Basket -4AN return looks like

Stock fuel tank connections with -4AN Return

Comparing the DW300ltr pump with Walbro 485

Parts for the Supply and Return lines

1x SUM-220984 PTFE HOSE -6AN X 10'/3M ROLL

1xSUM-220992 PTFE HOSE -8AN X 10'/3M ROLL

2x EAR-800108ERL -8AN ST. SWIVEL-SEAL FITTING

2x EAR-800106ERL -6AN ST. SWIVEL-SEAL FITTING

1x SUM-220166 -6 O-RING TO -6 FLARE FITTING (for FPR, replaces the -6 to -4 fitting)

1x Earl's Performance 9893068ERL Female -6AN to Male -8AN Expander (for rails T-piece)

Parts for the Fuel Basket

1x SUM-220650 -6AN X 1/8 90 JIC NPT (This replaces 1/8 to -4AN fitting, where it screws into the replacement part of the basket regulator)

1x RUS-661250 ELBOW 90DEG FLARE BULKHEAD #6 (This goes into the top of the fuel basket)

2x RUS-683900 -6AN STAT O SEAL (These fit either side of the RUS-661250 fitting)

1x EAR-592406ERL BULKHEAD NUT -6 (This fits on the fuel side of the RUS-661250 fitting)

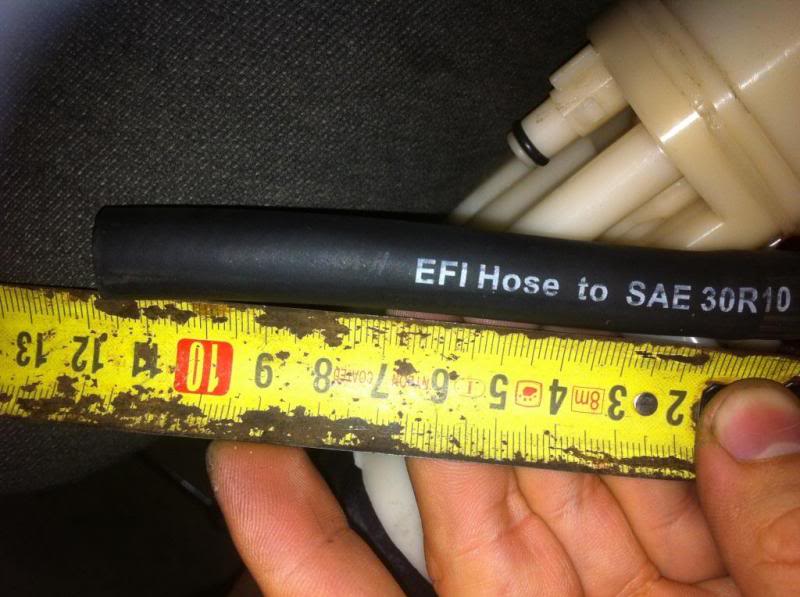

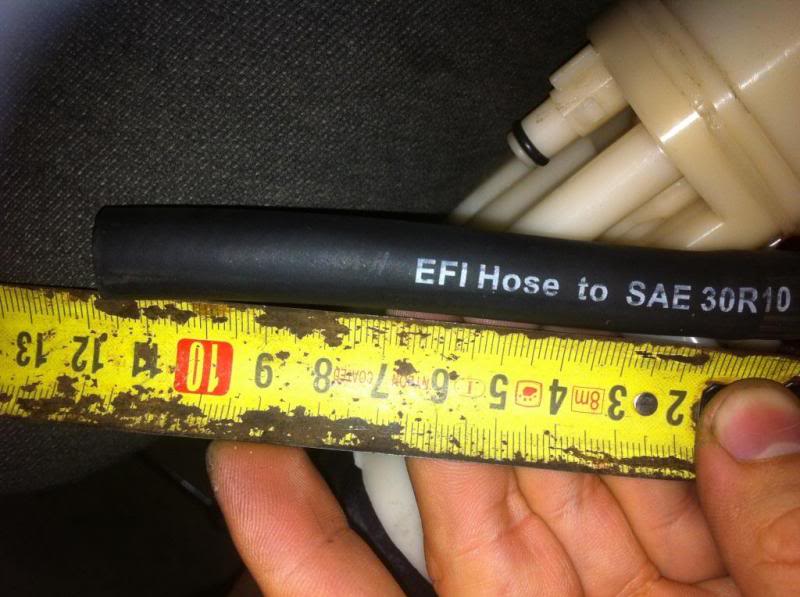

1x 5.5Ē Submersible EFI Hose to SAE 30R10 (may have to ebay this, I got it locally)

1x Summit Racing SUM-220711 6AN Twist-Tite Swivel Hose End 90 degree

1x Summit Racing SUM-220706 -6AN Twist-Tite Swivel Hose End 45 degree

1x Earl's Performance 985068ER -6AN MALE Straight Cut O-Ring to -8AN MALE Fitting

1x http://shop.cj-motorsports.com/CJM-F...fpofitting.htm CJM Fuel Pump Output Fitting (You may not need Earls 985068ER if Charles can replace the -6AN fitting he sells with it for you)

Other Parts

1x http://shop.cj-motorsports.com/Walbr...-walbro485.htm Walbro 485lph E85 Pump

1x 32-44mm hose clamp (I had this laying around but get one with smallest screwing mechanism as possible)

Some heat shrink and a soldering iron

Once I get the E-Flex sensor I will add that the guide !

If you didnít have a RFS already you would need rails and the lines for the rails plus the fuel basket fuel regulator replacement part from CJM.

Here is what the AAM stage 1 RFS Fuel Basket -4AN return looks like

Stock fuel tank connections with -4AN Return

Comparing the DW300ltr pump with Walbro 485

Parts for the Supply and Return lines

1x SUM-220984 PTFE HOSE -6AN X 10'/3M ROLL

1xSUM-220992 PTFE HOSE -8AN X 10'/3M ROLL

2x EAR-800108ERL -8AN ST. SWIVEL-SEAL FITTING

2x EAR-800106ERL -6AN ST. SWIVEL-SEAL FITTING

1x SUM-220166 -6 O-RING TO -6 FLARE FITTING (for FPR, replaces the -6 to -4 fitting)

1x Earl's Performance 9893068ERL Female -6AN to Male -8AN Expander (for rails T-piece)

Parts for the Fuel Basket

1x SUM-220650 -6AN X 1/8 90 JIC NPT (This replaces 1/8 to -4AN fitting, where it screws into the replacement part of the basket regulator)

1x RUS-661250 ELBOW 90DEG FLARE BULKHEAD #6 (This goes into the top of the fuel basket)

2x RUS-683900 -6AN STAT O SEAL (These fit either side of the RUS-661250 fitting)

1x EAR-592406ERL BULKHEAD NUT -6 (This fits on the fuel side of the RUS-661250 fitting)

1x 5.5Ē Submersible EFI Hose to SAE 30R10 (may have to ebay this, I got it locally)

1x Summit Racing SUM-220711 6AN Twist-Tite Swivel Hose End 90 degree

1x Summit Racing SUM-220706 -6AN Twist-Tite Swivel Hose End 45 degree

1x Earl's Performance 985068ER -6AN MALE Straight Cut O-Ring to -8AN MALE Fitting

1x http://shop.cj-motorsports.com/CJM-F...fpofitting.htm CJM Fuel Pump Output Fitting (You may not need Earls 985068ER if Charles can replace the -6AN fitting he sells with it for you)

Other Parts

1x http://shop.cj-motorsports.com/Walbr...-walbro485.htm Walbro 485lph E85 Pump

1x 32-44mm hose clamp (I had this laying around but get one with smallest screwing mechanism as possible)

Some heat shrink and a soldering iron

#2

Step 1

Attach the Earl's Performance 9893068ERLfitting to the bottom of the rails T piece, now we have a -8AN connection.

Step 2

I don’t have a picture but unscrew the -4 straight cut to male -6AN off the bottom of the FPR and replace it with SUM-220166

Step 3

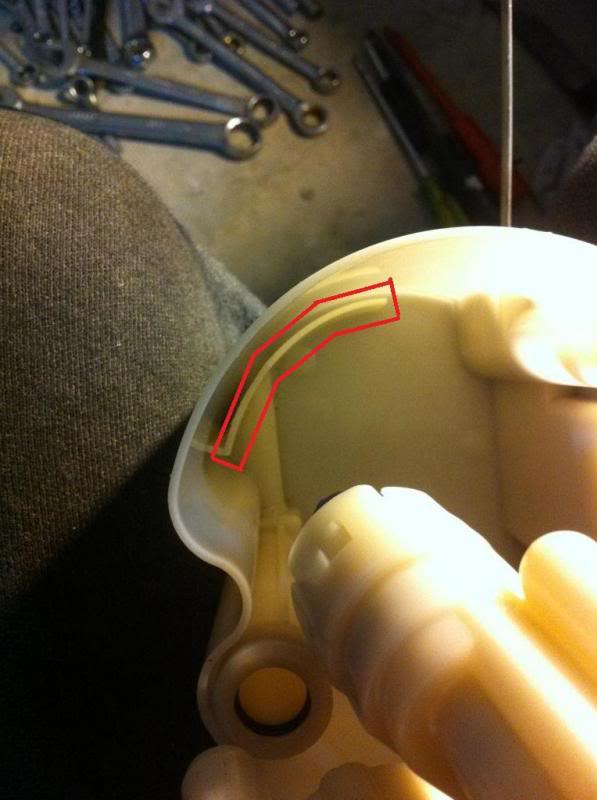

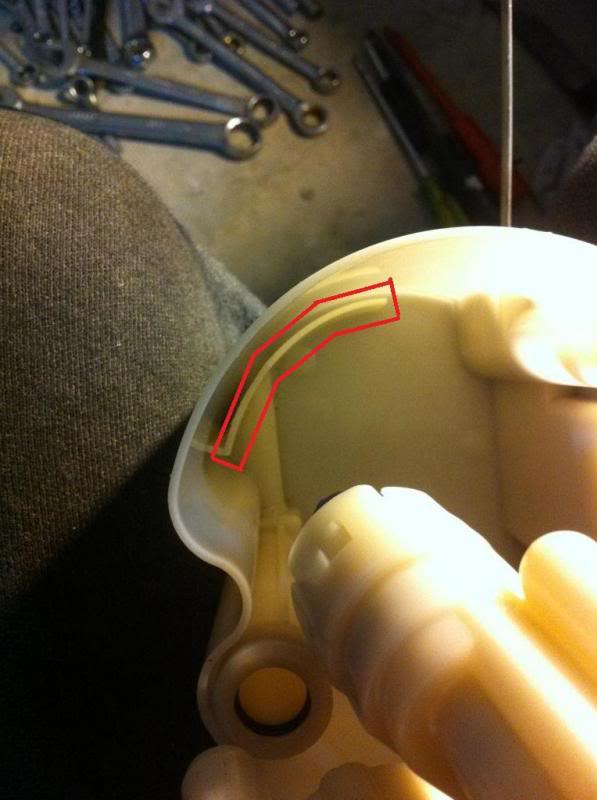

Take off the -4AN parts off the fuel basket. You will need to drill out the hole a little more to fit the bigger -6AN bulk head fitting RUS-661250. You will need to also flatten all the raised ridges so the fitting fits flush. I made the hole too close to the edge of the basket, make it where the red outline is.

You will need to cut one of the -6AN Stat o Seals RUS-683900 so it fits.

Step 4

Fit the bulkhead fitting RUS-661250 with the Stat o Seal either side of it. Then put the nut EAR-592406ERL on the end.

Step 5

I don’t have a specific picture but fit the 1/8NPT 90 degree to -6AN fitting SUM-220650 into the regulator replacement part.

Step 6

You will need pretty much exactly 11.5 cm of the EFI Hose to SAE 30R10 of the submersible fuel line

Attach the Summit Racing SUM-220711 90 degree to one end of the hose and the Summit Racing SUM-220706 45 degree to the other end.

Step 7

Now we need to prepare the fuel pump, two things need to happen.

1. The top barb off the tank needs to be cut off, see the red line.

2. The other thing which I didn’t take a pic of is filling down the port the metal o-ring goes over that holds the fuel filter in place. You can either get a larger retaining o-ring clip or file the port down so the stock one fits. Don’t fit the filter until the end.

Step 8

Now the annoying hardish part. A few things must be modified to the basket itself.

1. Need to cut the bottom of the fuel pump canister holder just below the locking mechanism tabs.

2. You will need to make a slot to fit the clamp through, right near the 3 structural lines. I first made the cut (with a stanley knife) just below the 3 lines but later found I needed to make it 1-2mm further into the lines, so do it where the red line is and down to where you see the clamp currently is.

3. Insert the clamp and draw a black line just after the ridge where it hits the other side. This will help you know where to cut the other side

It should now look like this

You will need to you some multi grips to shape the clamp otherwise you wont be able to get the pump in, you may want to fit the pump in while you do this.

*Make sure the black rubber fitting goes on top of the fuel pump barb you cut previously. The black rubber thing may be stuck inside the fuel assembly still, if it is just leave it in there.

4. You will then need to allow the black hose to fit closer to the side of the fuel basket so you need to cut the 3 structural lines and shave off a bit up the top as you can see in the red.

*NOTE* I forgot to mention you need to cut off the fuel pump plug and solder the wires and use heat shrink.

Step 9

If you did everything correctly you should see very little space between the black rubber and the pump.

This is what it looks like with the barb cut

This is what it looks like if you didn’t cut the barb on top of the fuel pump

You need as much room at the bottom of the fuel assembly as possible.

It should look like this

You will want to make sure when you tighten the clamp the screw assembly is pushed as close to the red line as possible.

Step 10

Fit the bottom pump assembly and it should look like this

You will see I initially used a -6AN female to -8 male expander which was wrong as there is not enough room, that is why you replace the fitting that comes with it for a straight cut -6 to -8AN male fitting.

In the fuel tank you can see the space

And your going to need some 1000cc injectors at least ! I wanted ID1000s but got a new set of DW1000 for a good price.

Step 11

You will need to run the lines and attach the fittings to the ends but that’s easy, just don’t attach the fittings to the tank side otherwise you won’t get them to fit when feeding the lines through.

Tip: feed through a coat hanger or some wire from inside the car down along outside of fuel tank and out where the stock lines run along the car. Then tie the -6 and -8an lines on separately and pull them up into the tank from inside the car.

DONE - this guide was almost as painful as the above!

Attach the Earl's Performance 9893068ERLfitting to the bottom of the rails T piece, now we have a -8AN connection.

Step 2

I don’t have a picture but unscrew the -4 straight cut to male -6AN off the bottom of the FPR and replace it with SUM-220166

Step 3

Take off the -4AN parts off the fuel basket. You will need to drill out the hole a little more to fit the bigger -6AN bulk head fitting RUS-661250. You will need to also flatten all the raised ridges so the fitting fits flush. I made the hole too close to the edge of the basket, make it where the red outline is.

You will need to cut one of the -6AN Stat o Seals RUS-683900 so it fits.

Step 4

Fit the bulkhead fitting RUS-661250 with the Stat o Seal either side of it. Then put the nut EAR-592406ERL on the end.

Step 5

I don’t have a specific picture but fit the 1/8NPT 90 degree to -6AN fitting SUM-220650 into the regulator replacement part.

Step 6

You will need pretty much exactly 11.5 cm of the EFI Hose to SAE 30R10 of the submersible fuel line

Attach the Summit Racing SUM-220711 90 degree to one end of the hose and the Summit Racing SUM-220706 45 degree to the other end.

Step 7

Now we need to prepare the fuel pump, two things need to happen.

1. The top barb off the tank needs to be cut off, see the red line.

2. The other thing which I didn’t take a pic of is filling down the port the metal o-ring goes over that holds the fuel filter in place. You can either get a larger retaining o-ring clip or file the port down so the stock one fits. Don’t fit the filter until the end.

Step 8

Now the annoying hardish part. A few things must be modified to the basket itself.

1. Need to cut the bottom of the fuel pump canister holder just below the locking mechanism tabs.

2. You will need to make a slot to fit the clamp through, right near the 3 structural lines. I first made the cut (with a stanley knife) just below the 3 lines but later found I needed to make it 1-2mm further into the lines, so do it where the red line is and down to where you see the clamp currently is.

3. Insert the clamp and draw a black line just after the ridge where it hits the other side. This will help you know where to cut the other side

It should now look like this

You will need to you some multi grips to shape the clamp otherwise you wont be able to get the pump in, you may want to fit the pump in while you do this.

*Make sure the black rubber fitting goes on top of the fuel pump barb you cut previously. The black rubber thing may be stuck inside the fuel assembly still, if it is just leave it in there.

4. You will then need to allow the black hose to fit closer to the side of the fuel basket so you need to cut the 3 structural lines and shave off a bit up the top as you can see in the red.

*NOTE* I forgot to mention you need to cut off the fuel pump plug and solder the wires and use heat shrink.

Step 9

If you did everything correctly you should see very little space between the black rubber and the pump.

This is what it looks like with the barb cut

This is what it looks like if you didn’t cut the barb on top of the fuel pump

You need as much room at the bottom of the fuel assembly as possible.

It should look like this

You will want to make sure when you tighten the clamp the screw assembly is pushed as close to the red line as possible.

Step 10

Fit the bottom pump assembly and it should look like this

You will see I initially used a -6AN female to -8 male expander which was wrong as there is not enough room, that is why you replace the fitting that comes with it for a straight cut -6 to -8AN male fitting.

In the fuel tank you can see the space

And your going to need some 1000cc injectors at least ! I wanted ID1000s but got a new set of DW1000 for a good price.

Step 11

You will need to run the lines and attach the fittings to the ends but that’s easy, just don’t attach the fittings to the tank side otherwise you won’t get them to fit when feeding the lines through.

Tip: feed through a coat hanger or some wire from inside the car down along outside of fuel tank and out where the stock lines run along the car. Then tie the -6 and -8an lines on separately and pull them up into the tank from inside the car.

DONE - this guide was almost as painful as the above!

Last edited by R6n350GT; 08-22-2013 at 11:04 PM.

#3

Mistakes to Avoid

Step 8 & 9 – if you don’t cut the slot into the 3 lines and push the locking mechanism into the red line then this will happen

If you did it correctly it will look like this

Once you are fitting the bottom of the fuel pump assembly in WATCH OUT FOR THIS SWIRL JET WALL. The Fuel regulator port hits it and you cant compress the fuel basket so you cant screw it down to the tank when fitting it, just need to jiggle it so it slides beside this wall and not hitting the top. This stumped me for ages !!

Step 8 & 9 – if you don’t cut the slot into the 3 lines and push the locking mechanism into the red line then this will happen

If you did it correctly it will look like this

Once you are fitting the bottom of the fuel pump assembly in WATCH OUT FOR THIS SWIRL JET WALL. The Fuel regulator port hits it and you cant compress the fuel basket so you cant screw it down to the tank when fitting it, just need to jiggle it so it slides beside this wall and not hitting the top. This stumped me for ages !!

Last edited by R6n350GT; 08-22-2013 at 11:24 PM.

#4

Great write up, very detailed.

Another option for fuel pump housing outlet adapter that's much cheaper and more compact than the CJM fitting.

http://www.summitracing.com/parts/rus-644003

Used it for years with no leakage before upgrading to CJM twin pump.

Another option for fuel pump housing outlet adapter that's much cheaper and more compact than the CJM fitting.

http://www.summitracing.com/parts/rus-644003

Used it for years with no leakage before upgrading to CJM twin pump.

The following users liked this post:

R6n350GT (08-23-2013)

#6

The following users liked this post:

Frankieg35 (08-23-2013)

#7

I gotta ask though. Why go through all the trouble of retrofitting in a large pump? For not too much more money, you could have just dropped an aluminum fuel cell with internal pump in the trunk. Would have been alot less effort. Then with a flick of a switch, you could run 91 or E85 on a whim.

Not an internal pump, but same idea.

Not an internal pump, but same idea.

Last edited by WhosUrBuddiee; 08-23-2013 at 08:47 AM.

Trending Topics

#8

Thanks, but as more and more people use E85 they will need bigger pumps and new setup. Re fuel cell, the above apart from pump cost under $200.

#9

No one from this community will be doing E85 conversions. G35Driver is completely focused on Hellaflush, not performance. Ive been here 9 years and you are probably the second or third person to ever do it to a G35.

I hope you are in an area where E85 is easy to find. I am on the LS1 boards alot, where performance is still main priority. Fuel cells are popular because you can run pump gas and E85 with the flip of a switch and map change. A little more money, but easier install and alot of people dont have access to E85 all the time.

I hope you are in an area where E85 is easy to find. I am on the LS1 boards alot, where performance is still main priority. Fuel cells are popular because you can run pump gas and E85 with the flip of a switch and map change. A little more money, but easier install and alot of people dont have access to E85 all the time.

Last edited by WhosUrBuddiee; 08-23-2013 at 10:33 AM.

#11

Herrschaft, there's a guy a thread or two down working on that as well. Haltech can handle the tuning of it and adjust accordingly for whatever amount of e85 vs. standard gas you're using.

https://g35driver.com/forums/forced-...onversion.html

https://g35driver.com/forums/forced-...onversion.html

#13

#14

#15

Great to see someone else doing a flex fuel conversion. I'll be watching this thread to see how it's working out for you. Nice that you have the skills and time to do this yourself. What type of FI setup do you have? Vortech? I couldn't tell from the pics.

Best of luck with this!!

Best of luck with this!!

upgraded turbo to 35r with T3 flange

FMIC

FRS as you see able

Haltech plug and play ecu

Fujitsubo exhaust

GTM Exedy Twin Flywheel / Clutch with chrome moly pivot ball

Built engine, forged eagle rods, wiesco 8.5:1 pistons, BC stage 2 cams, upgraded BC springs and retainers, ACL Race bearings

HR cooling block mod

HR head gasket

HR head bolts

ARP main studs