My NEW FMIC mounted... PE TT MT Sedan

#31

Hey Gus

Thought I'd chime in. Thanks George, rcdash, athenG for the kind words. I have indeed been just sickened by the level of misinformation on the forums, I am speaking in general, mostly on the other board. I;ve also been very busy with work and other projects to work on the car extensively or spend time on the forums like I used to.

I do have the next couple of days off, and will chime in on some of the discussion on compressor efficiencies. Since the posts of Squill and my own from a couple of years back, I have devised a detailed spreadsheet that calculates and graphs compressor efficiencies much more precisely. In several words, my compressor efficiency for a 3.5 L engine on the PE 1420 turbo is PERFECT. The problem is not that, it's turbine AR that's mated to that compressor that introduces way more back pressure that I would want for even peakier number. Yes, not the compressor...that's half the story, but the turbine side of things is the culprit. Unfortunately, though turbine compressor maps do exist, they are largely unpublished and are difficult to interpret, even for many engineers. Hence, we are left to other devices, overall very difficult ot implement on a personal budget, and very complicated procedures to determining ideal turbine size. hence, we are largely relegated to trial and error in picking it. The turbine size will determine the spool characteristic of a setup...i.e. how well the efficiencies of the COMPRESSOR side are realized in a given load/rpm condition. My setup delivers very good midrange and acceptable, though not ideal, top end... So, I'll live with that, in short, as the alternative is a lot of money for extra 30 hp on the top end, with would make my setup ideal (at least as far as the "old" VQ35 allows).

Thought I'd chime in. Thanks George, rcdash, athenG for the kind words. I have indeed been just sickened by the level of misinformation on the forums, I am speaking in general, mostly on the other board. I;ve also been very busy with work and other projects to work on the car extensively or spend time on the forums like I used to.

I do have the next couple of days off, and will chime in on some of the discussion on compressor efficiencies. Since the posts of Squill and my own from a couple of years back, I have devised a detailed spreadsheet that calculates and graphs compressor efficiencies much more precisely. In several words, my compressor efficiency for a 3.5 L engine on the PE 1420 turbo is PERFECT. The problem is not that, it's turbine AR that's mated to that compressor that introduces way more back pressure that I would want for even peakier number. Yes, not the compressor...that's half the story, but the turbine side of things is the culprit. Unfortunately, though turbine compressor maps do exist, they are largely unpublished and are difficult to interpret, even for many engineers. Hence, we are left to other devices, overall very difficult ot implement on a personal budget, and very complicated procedures to determining ideal turbine size. hence, we are largely relegated to trial and error in picking it. The turbine size will determine the spool characteristic of a setup...i.e. how well the efficiencies of the COMPRESSOR side are realized in a given load/rpm condition. My setup delivers very good midrange and acceptable, though not ideal, top end... So, I'll live with that, in short, as the alternative is a lot of money for extra 30 hp on the top end, with would make my setup ideal (at least as far as the "old" VQ35 allows).

#32

#33

#34

The JWT 700bb is using a GT28RS compressor wheel right?

Here are some numbers I have in my spreadsheet using the formula in Corky Bell's book to calculate airflow rate of an engine with and w/o a turbo, and I verified the number with a turbo calculator (http://www.squirrelpf.com/turbocalc/). The turbo calculator is more advance because you can specify a different VE on a different RPM range, you can also set the IAT.

Here's what I got using the formula but I only used a VE of 90% on the entire rpm range for simplicity purposes. I also didn't make adjustment base on the IAT and altitude so this is a rough estimate on how much airflow is needed on our engine. I only copied 10psi-20psi.

LOL I posted this at 1am EST and I just took a sleeping pill an hour ago so I'm half asleep now and have no idea if I'm making any sense... lol

Basic Airflow rate W/O turbo = (cidxrpmx.05xEv)/1728

Flow rate is in cfm and displacement is in cubic inches.

Ev= volumetric efficiency

.5= due to four stroke engine fill its cylinder only 1/2 of the time

1728 =convert cubic inches to cubic feet

Example: VQ cid = 215, rpm = 7000, Ev = 90%

Basic engine cfm = (215x7000x0.5x90)/1728 = 391.92 cfm

Airflow rate with turbo/SC = pressure ratio x basic engine cfm

let us use 2.37bar (20psi)

2.37x391.92 = 928.9cfm

lbs/min conversion = cfm * .069

928.9cfm x .069 = 64.1 lbs/min

In the end you want a turbo that can flow 64.1lbs/min or 928.9cfm at 7000rpm, since Gurgen has a TT then you can cut the flow in half because there are 2 turbo.

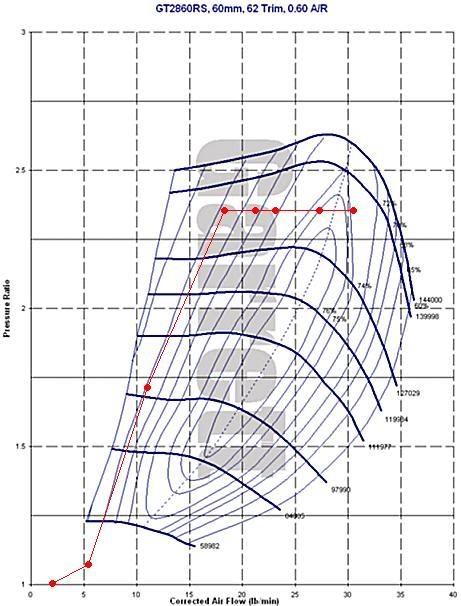

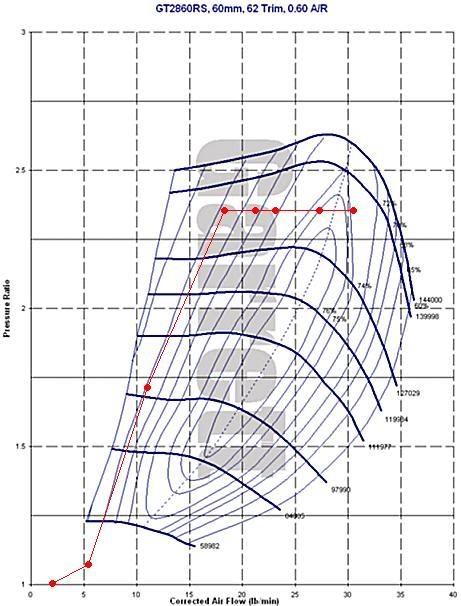

Here are 2 maps I got from the turbo calculator website. I set the full boost to hit at 4100rpm on this graph.

18psi

20psi

Maybe Gurgen has a better or more accurate calculation..

Here are some numbers I have in my spreadsheet using the formula in Corky Bell's book to calculate airflow rate of an engine with and w/o a turbo, and I verified the number with a turbo calculator (http://www.squirrelpf.com/turbocalc/). The turbo calculator is more advance because you can specify a different VE on a different RPM range, you can also set the IAT.

Here's what I got using the formula but I only used a VE of 90% on the entire rpm range for simplicity purposes. I also didn't make adjustment base on the IAT and altitude so this is a rough estimate on how much airflow is needed on our engine. I only copied 10psi-20psi.

LOL I posted this at 1am EST and I just took a sleeping pill an hour ago so I'm half asleep now and have no idea if I'm making any sense... lol

Basic Airflow rate W/O turbo = (cidxrpmx.05xEv)/1728

Flow rate is in cfm and displacement is in cubic inches.

Ev= volumetric efficiency

.5= due to four stroke engine fill its cylinder only 1/2 of the time

1728 =convert cubic inches to cubic feet

Example: VQ cid = 215, rpm = 7000, Ev = 90%

Basic engine cfm = (215x7000x0.5x90)/1728 = 391.92 cfm

Airflow rate with turbo/SC = pressure ratio x basic engine cfm

let us use 2.37bar (20psi)

2.37x391.92 = 928.9cfm

lbs/min conversion = cfm * .069

928.9cfm x .069 = 64.1 lbs/min

In the end you want a turbo that can flow 64.1lbs/min or 928.9cfm at 7000rpm, since Gurgen has a TT then you can cut the flow in half because there are 2 turbo.

Code:

This is lbs/min rpm 10psi 11psi 12psi 13psi 14psi 15psi 16psi 17psi 18psi 19psi 20psi 0 200 1.3 1.4 1.4 1.5 1.5 1.6 1.6 1.7 1.7 1.8 1.8 400 2.6 2.7 2.8 2.9 3.0 3.1 3.2 3.4 3.5 3.6 3.7 600 3.9 4.1 4.2 4.4 4.5 4.7 4.9 5.0 5.2 5.4 5.5 800 5.2 5.4 5.6 5.8 6.1 6.2 6.5 6.7 6.9 7.1 7.3 1000 6.5 6.8 7.0 7.3 7.6 7.8 8.1 8.4 8.7 8.9 9.2 1200 7.8 8.1 8.4 8.8 9.1 9.4 9.7 10.1 10.4 10.7 11.0 1400 9.1 9.5 9.8 10.2 10.6 10.9 11.4 11.7 12.1 12.5 12.8 1600 10.4 10.8 11.2 11.7 12.1 12.5 13.0 13.4 13.8 14.3 14.6 1800 11.7 12.2 12.7 13.1 13.6 14.0 14.6 15.1 15.6 16.1 16.5 2000 13.0 13.5 14.1 14.6 15.1 15.6 16.2 16.8 17.3 17.8 18.3 2200 14.3 14.9 15.5 16.1 16.7 17.2 17.8 18.4 19.0 19.6 20.1 2400 15.6 16.2 16.9 17.5 18.2 18.7 19.5 20.1 20.8 21.4 22.0 2600 16.9 17.6 18.3 19.0 19.7 20.3 21.1 21.8 22.5 23.2 23.8 2800 18.2 18.9 19.7 20.4 21.2 21.9 22.7 23.5 24.2 25.0 25.6 3000 19.5 20.3 21.1 21.9 22.7 23.4 24.3 25.1 26.0 26.8 27.5 3200 20.8 21.6 22.5 23.4 24.2 25.0 26.0 26.8 27.7 28.6 29.3 3400 22.1 23.0 23.9 24.8 25.7 26.5 27.6 28.5 29.4 30.3 31.1 3600 23.4 24.3 25.3 26.3 27.3 28.1 29.2 30.2 31.2 32.1 33.0 3800 24.7 25.7 26.7 27.7 28.8 29.7 30.8 31.9 32.9 33.9 34.8 4000 26.0 27.0 28.1 29.2 30.3 31.2 32.5 33.5 34.6 35.7 36.6 4200 27.3 28.4 29.5 30.7 31.8 32.8 34.1 35.2 36.3 37.5 38.5 4400 28.6 29.7 30.9 32.1 33.3 34.3 35.7 36.9 38.1 39.3 40.3 4600 29.9 31.1 32.3 33.6 34.8 35.9 37.3 38.6 39.8 41.1 42.1 4800 31.2 32.5 33.7 35.0 36.3 37.5 38.9 40.2 41.5 42.8 43.9 5000 32.5 33.8 35.2 36.5 37.9 39.0 40.6 41.9 43.3 44.6 45.8 5200 33.7 35.2 36.6 38.0 39.4 40.6 42.2 43.6 45.0 46.4 47.6 5400 35.0 36.5 38.0 39.4 40.9 42.1 43.8 45.3 46.7 48.2 49.4 5600 36.3 37.9 39.4 40.9 42.4 43.7 45.4 46.9 48.5 50.0 51.3 5800 37.6 39.2 40.8 42.3 43.9 45.3 47.1 48.6 50.2 51.8 53.1 6000 38.9 40.6 42.2 43.8 45.4 46.8 48.7 50.3 51.9 53.5 54.9 6200 40.2 41.9 43.6 45.3 46.9 48.4 50.3 52.0 53.7 55.3 56.8 6400 41.5 43.3 45.0 46.7 48.5 49.9 51.9 53.7 55.4 57.1 58.6 6600 42.8 44.6 46.4 48.2 50.0 51.5 53.5 55.3 57.1 58.9 60.4 6800 44.1 46.0 47.8 49.7 51.5 53.1 55.2 57.0 58.8 60.7 62.3 7000 45.4 47.3 49.2 51.1 53.0 54.6 53.6 55.4 57.2 59.0 64.1

18psi

20psi

Maybe Gurgen has a better or more accurate calculation..

Last edited by FI'ed G; 02-21-2009 at 08:59 AM.

#35

Thanks for that - very interesting - need some time to work through it but looks spot on at first glance.

One thing I don't understand is why my power drops off after 6500 rpm, but by looking at the way you mapped it out, the turbos are moving into higher efficiency at higher rpm. Hmmm... Maybe my cams are just closing the intake valves too soon? (JWT S2)

One thing I don't understand is why my power drops off after 6500 rpm, but by looking at the way you mapped it out, the turbos are moving into higher efficiency at higher rpm. Hmmm... Maybe my cams are just closing the intake valves too soon? (JWT S2)

#38

#40

You dont have to post here if you dont have anything to contribute

Are you talking about the boost line? If you dont change the Target HP and if you lean out the A/F then it will take less boost to achieve the target HP but you are right coz I set the target A/f to 9.0:1 and the boost line went down even further It should be loosing power at that A/F..

It should be loosing power at that A/F..

It should be loosing power at that A/F..

It should be loosing power at that A/F..

#41

Are you talking about the boost line? If you dont change the Target HP and if you lean out the A/F then it will take less boost to achieve the target HP but you are right coz I set the target A/f to 9.0:1 and the boost line went down even further It should be loosing power at that A/F..

It should be loosing power at that A/F..

It should be loosing power at that A/F..

It should be loosing power at that A/F..

#42

Gurgen, car is looking amazing, that IC is a monster bro looking great. I will say the knowledge and time Gurgen has invested in his car is amazing and really elevates the knowledge that we all should understand our vq's. I always look forward to hearing from Gurgen and his reason and study behind his decisions made on his car.

Gurgen, car is looking amazing, that IC is a monster bro looking great. I will say the knowledge and time Gurgen has invested in his car is amazing and really elevates the knowledge that we all should understand our vq's. I always look forward to hearing from Gurgen and his reason and study behind his decisions made on his car.

Thread

Thread Starter

Forum

Replies

Last Post

yosip1115

Forced Induction

8

01-28-2016 02:51 PM

I'd like to make one for the 700bb turbo. Does water injection have any impact on turbine efficiency by lowering EGTs? I would think it would be one of the few non-mechanical methods that would help...

I'd like to make one for the 700bb turbo. Does water injection have any impact on turbine efficiency by lowering EGTs? I would think it would be one of the few non-mechanical methods that would help...