DIY: Clean your throttle bodies

#46

#48

#49

Registered User

iTrader: (7)

well i just have a small torque wrench on which i can use hex key attachments and torque it down. But ya i also tightened it real good, i am more worried about having it overtightened and crack the plastic plenum some how. I know not really possible unless the bolts are REALLY overtightened but ill check just to be sure.

Thanks again!

Thanks again!

#51

#53

how the hell does someone measure torque settings on these small Hex screws?

all I've got is a huge *** torque wrench I don't see how I can attach a small Hex tool to the end to measure the TQ, how did u do it Kool Yaar?

and WTH is Kool Yaar anyway? is it like saying cool yah just in a funny accent?

all I've got is a huge *** torque wrench I don't see how I can attach a small Hex tool to the end to measure the TQ, how did u do it Kool Yaar?

and WTH is Kool Yaar anyway? is it like saying cool yah just in a funny accent?

#54

#55

#56

#58

Registered User

iTrader: (1)

Join Date: Feb 2007

Location: Bay Area, CA

Posts: 665

Likes: 0

Received 0 Likes

on

0 Posts

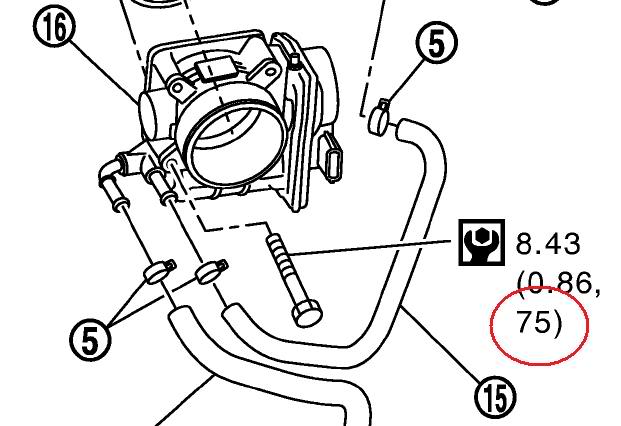

8.43 (0.86, 75) --- Even though the last number SHOULD refer to ft/lb (as it usually does in the factory service manual), I'm sure this was a mistake and it actually meant to say to in/lb. Roughly speaking, 8.43Nm = 0.86kg/m = 75in/lb = 6ft/lb.

That small screw was NOT made for 75ft/lb of torque. LOL Heck, our lug nuts are 80ft/lb!!

That small screw was NOT made for 75ft/lb of torque. LOL Heck, our lug nuts are 80ft/lb!!

#59

Registered User

iTrader: (7)

^ +1 when i got my small torque wrench yesterday i saw the reading were in in/lb so i figured the PDF meant 75in/lb so i tightened mine to 75in/lb yesterday, i was about to post that today.

@Defratos I have a tool similar to this but much cheaper, it is used for such small torquing needs.

@Defratos I have a tool similar to this but much cheaper, it is used for such small torquing needs.

Last edited by kool_yaar; 03-18-2010 at 01:55 AM.

#60

you should see the dirt that came out of my dad's '02 pathfinder (160K miles). I had to use 3 shop towels and a full can of TB cleaner lol.

you should see the dirt that came out of my dad's '02 pathfinder (160K miles). I had to use 3 shop towels and a full can of TB cleaner lol.

need to mine soon

need to mine soon