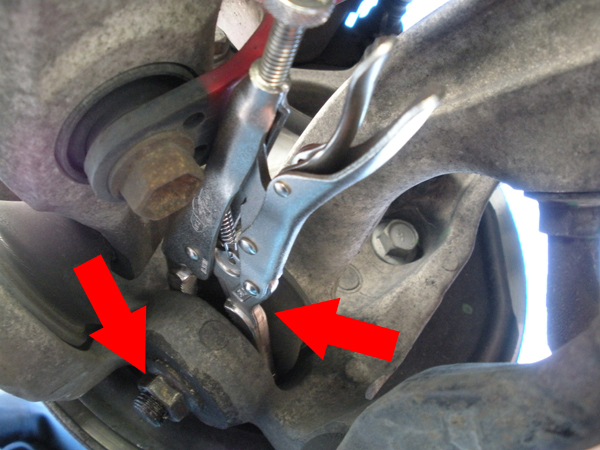

Ball joint stud spinning while trying to remove nut!

#1

The dealer told me my compression rods need to be changed. So I decided to save hundreds of dollars and just change the bushings by removing the compression rods. This is my first time working on suspension and this issue has got me frustrated to the point of almost tapping out and hiring a mechanic to come to my garage. And quitting is not in my nature..

I have the car on all 4 jack stands. Front passenger wheel removed, caliper, caliper brackets, rotor... removed. I started by removing the cotter pin from the compression rod ball joint stud which would not budge and I ended up having to drill it out... Then I felt great for about a minute and did not expect what was about to come.. I used my new impact gun on the ball joint nut and it just spins the ball joint stud in its socket..

Is there a proven way to do this? I have even tried jacking up the knuckle/LCA and even jacking directly on the bolt and using an open ended wrench but it just kept spinning the stud... it doesn't take much force to spin this stud..

My car has been up on stands for days now.. this problem has me stumped. I have heard of using a picklefork? Will it even fit in the small area we have to work with?

Note: the underbrace is still connected to the vehicle and not removed. The bushing side of the compression rod has not been removed yet.

I feel like I have sprayed half a bottle of PB blaster on the stud/nut. I have even used a torch to heat up the nut a couple times.

I have the car on all 4 jack stands. Front passenger wheel removed, caliper, caliper brackets, rotor... removed. I started by removing the cotter pin from the compression rod ball joint stud which would not budge and I ended up having to drill it out... Then I felt great for about a minute and did not expect what was about to come.. I used my new impact gun on the ball joint nut and it just spins the ball joint stud in its socket..

Is there a proven way to do this? I have even tried jacking up the knuckle/LCA and even jacking directly on the bolt and using an open ended wrench but it just kept spinning the stud... it doesn't take much force to spin this stud..

My car has been up on stands for days now.. this problem has me stumped. I have heard of using a picklefork? Will it even fit in the small area we have to work with?

Note: the underbrace is still connected to the vehicle and not removed. The bushing side of the compression rod has not been removed yet.

I feel like I have sprayed half a bottle of PB blaster on the stud/nut. I have even used a torch to heat up the nut a couple times.

Last edited by a_bains; 03-13-2013 at 11:49 PM.

#2

#4

#6

#7

Thanks for all the replies

I've already tried jacking the bottom of the knuckle assembly while turning the nut, there was no difference in tightness and the stud continued to turn. How do you suggest I apply downward force to the compression rod with enough force?

To the rest who suggested using a c-clamp or vice on the dust boot/stud, I think I will give that a go tomorrow. I will have to fiddle around with getting a proper grip on the stud as the neither the dust boot or the actual bolt below the nut give me much to grip on to.

I've already tried jacking the bottom of the knuckle assembly while turning the nut, there was no difference in tightness and the stud continued to turn. How do you suggest I apply downward force to the compression rod with enough force?

To the rest who suggested using a c-clamp or vice on the dust boot/stud, I think I will give that a go tomorrow. I will have to fiddle around with getting a proper grip on the stud as the neither the dust boot or the actual bolt below the nut give me much to grip on to.

Trending Topics

#8

What part of the stud did you clamp on to? Was this inside the dust boot or that little bit of stud below the nut?

#9

The following users liked this post:

a_bains (03-14-2013)

#10

Just picture creating as much friction as you can inside the joint, and definitely get some of that grease out of there using maf cleaner or something like that, thats what I used. clamp to the part directly on top of the nut and situate the other side of the clamp to the top of the compression rod.

#11

#12

Thanks for all the replies

I've already tried jacking the bottom of the knuckle assembly while turning the nut, there was no difference in tightness and the stud continued to turn. How do you suggest I apply downward force to the compression rod with enough force?

To the rest who suggested using a c-clamp or vice on the dust boot/stud, I think I will give that a go tomorrow. I will have to fiddle around with getting a proper grip on the stud as the neither the dust boot or the actual bolt below the nut give me much to grip on to.

I've already tried jacking the bottom of the knuckle assembly while turning the nut, there was no difference in tightness and the stud continued to turn. How do you suggest I apply downward force to the compression rod with enough force?

To the rest who suggested using a c-clamp or vice on the dust boot/stud, I think I will give that a go tomorrow. I will have to fiddle around with getting a proper grip on the stud as the neither the dust boot or the actual bolt below the nut give me much to grip on to.

#13

I got it off!!!!

Thank you all so much, my dad brought over his more powerful compressor, we turned up the PSI to about 145 and with the impact gun it came right off. Those were great suggestions and I was about to whip out the locking pliers next! A properly powered impact gun makes all the difference!

Thank you all so much, my dad brought over his more powerful compressor, we turned up the PSI to about 145 and with the impact gun it came right off. Those were great suggestions and I was about to whip out the locking pliers next! A properly powered impact gun makes all the difference!

Thread

Thread Starter

Forum

Replies

Last Post

Danielek

G35 Sedan V35 2003-06

9

05-01-2022 01:28 PM